Natural Killer Cells

A game-changing opportunity to advance allogeneic cell therapies

Rapid NK Cell Therapy Development Requires a Linearly Scalable Expansion Platform

Cell expansion platforms vary widely in their suitability for different applications, depending on key features such as parameter control, mixing dynamics, and scalability. These factors can make certain systems more optimal for specific processes or therapeutic modalities than others.

A Comparison of Bioreactor Platforms on the Market

| Vertical-Wheel® Bioreactor | Grex | Rocker Bag | Stirred Tank | |

|---|---|---|---|---|

| Gentle | ✓ | ✓ | ✓ | |

| Mini-Scale | ✓ | ✓ | ✓ | |

| Manufacturing-Scale | ✓ | ✓ | ✓ | |

| Perfusion-Capable | ✓ | ✓ | ✓ |

Cell therapies differ fundamentally from biologics—and allogeneic therapies from autologous ones—each with distinct process demands. As a result, tools designed for one may not suit the other. Allogeneic cell therapies, in particular, require finely tunable, linearly scalable expansion systems—making Vertical-Wheel Bioreactors a natural fit.

NK Cell Therapy Expansion and Scale-Up Challenges

Quality

3D culture hydrodynamics can dramatically impact cell yield, potency, purity, quality, and downstream differentiation efficiency.

Scalability

Relevant scale-down models and scalability potential are both critical requirements for rapid phase-appropriate scale-up.

Cost

The need for rapid, cost-effective platforms capable of addressing a variety of workflows in a smaller footprint.

Static vs. Vertical-Wheel Bioreactors

Static/2D platforms lack scalability and bioprocessing control required for scale-up optimization and manufacturing.

Vertical-Wheel® bioreactors enables temperature, agitation, pH and DO control control and monitoring from bench to manufacturing-scale.

Rocker Bag vs. Vertical-Wheel Bioreactors

Wave bags enable gentle mixing, but often lack adequate scale-down models, scale-up potential, and sufficient oxygen transfer for high cell densities at large-scale.

Vertical-Wheel Bioreactors enable working volumes from 60mL PD-scale up to 80L manufacturing-scale. Sterile connection to Repligen’s ATF Device enables gentle single-cell perfusion medium exchange to support high-density NK culture.

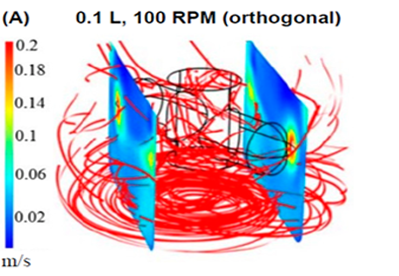

Stirred Tank vs. Vertical-Wheel Bioreactors

Stirred tank bioreactors require high power input which creates shear stress and increased heterogeneity in cell cultures.

Vertical-Wheel® bioreactors enables controllable power input for optimized mixing which achieves homogenous cell culture.

Optimize Allogeneic Cell Therapy Across Scales with Vertical-Wheel Bioreactors

| Vertical-Wheel | Working Volume | Agitation Control Range | |

|---|---|---|---|

| PBS-0.1 Mini | 60 - 100mL | 5 -100 RPM | Learn More |

| PBS-0.5 Mini | 100 - 500mL | 5 -100 RPM | Learn More |

| PBS-3 | 1.8 – 3.0L | 5 – 50 RPM (±1 RPM) | Learn More |

| PBS-15 | 9 – 15L | 5 – 50 RPM (±1 RPM) | Learn More |

| PBS-80 | 45 – 80L | 2 – 34 RPM (±1 RPM) | Learn More |

Vertical-Wheel Bioreactor vs. Static Bioreactor

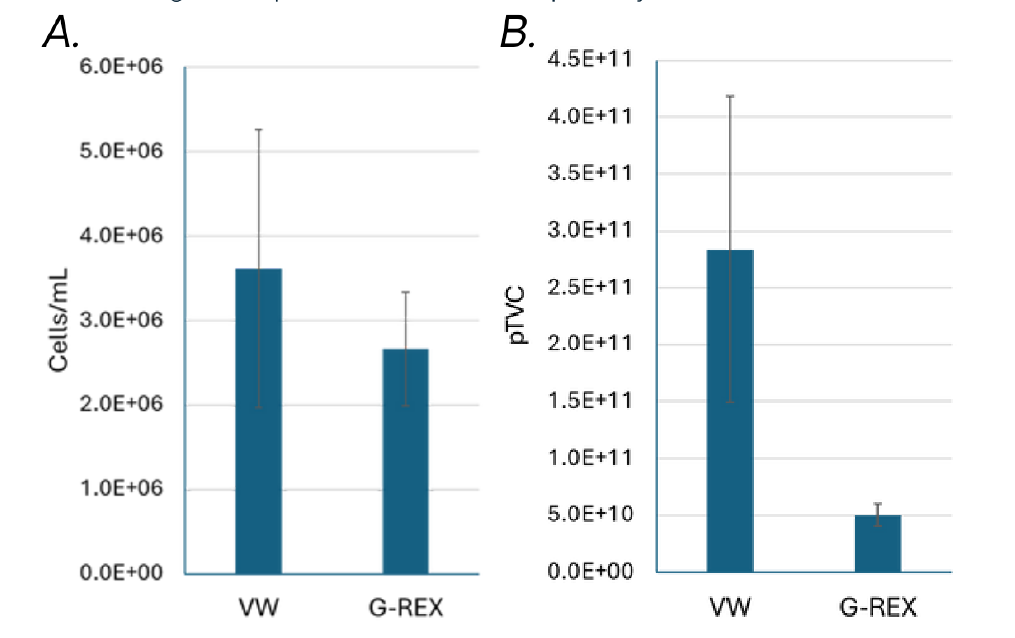

Figure A: Demonstrates that a PBS-3 Vertical-Wheel bioreactor was able to achieve an average of 3.6M cells/mL vs. G-Rex static bioreactor which achieved an average of 2.6M cells/mL. Figure B: Demonstrates a predicted total viable cell count after expansion is 2.8x1011 cells in a PBS-80 Vertical-Wheel bioreactor vs. 5x1010 cells in G-Rex static bioreactor.

Read the full application note»

Maximize your Natural Killer Cell Therapy Expansion with the Vertical-Wheel Scaling Calculator

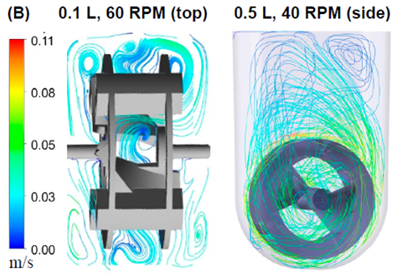

The PBS Biotech team has performed computational fluid dynamics (CFD) modeling to develop a method to translate agitation speeds across the different sized vessels. The CFD modeling shows that important volume average hydrodynamic variables can be maintained throughout scale-up (Dang, Borys 2021). These equations allow operators to define a working range of hydrodynamic variables at one scale and calculate the corresponding agitation rates at other modelled scales.

Try the Vertical-Wheel Scaling CalculatorReduce Cost and Increase Efficiency with Vertical-Wheel Bioreactors

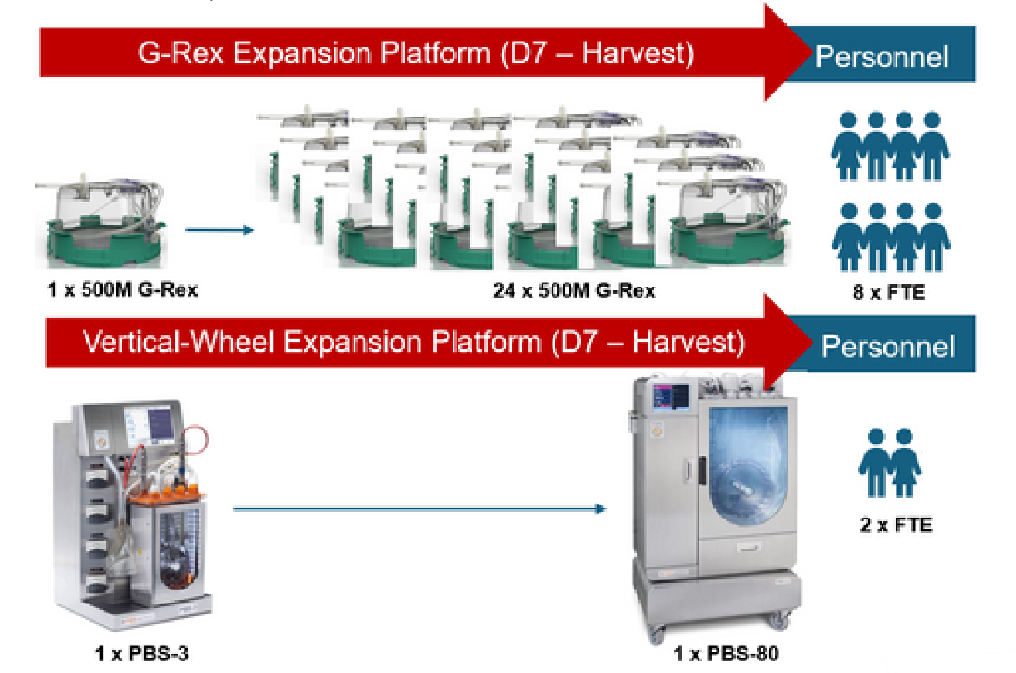

To produce 284 billion natural killer (NK) cells, G-Rex static bioreactor requires 2.5X the cost of media and disposable vessels and 4X more personnel than Vertical-Wheel bioreactor.

Read the full application note»

PBS Biotech’s Vertical-Wheel platform delivers precise power input for enhanced mixing, minimizing variability and elevating cell product quality. Demonstrating linear scalability from 60mL to 80L, Vertical-Wheel Bioreactors achieved 2.6M NK cells/mL with minimal optimization. Vertical-Wheel stands as a scalable, finely-tuned expansion platform for efficient production of NK cell therapies, improving both cost and performance in comparison to alternative technologies.

Try PBS Mini Vertical-Wheel Bioreactors, Risk Free!

Our Application Support Team partners with you every step of the way to help unlock the full potential of your NK cell therapy. When you generate data in collaboration with us, you receive 100% dedicated support . Transitioning to Vertical-Wheel Bioreactors means guaranteed end-to-end process support—boosting lab productivity, minimizing downtime, reducing costs, and maximizing cell therapy yield.